Manufacturing and Assembly

GLI has used cellular manufacturing, quality-at-the-source and lean production systems for over 20 years. It’s simple: We believe that good people will consistently produce high-quality products if given the tools and resources they need. Therefore, we have created a flexible, dynamic workplace designed to satisfy customers and provide fulfilling work for our employees.

GLI can perform the following operations in prototype and in high and low volume production: |

- Profile gear grinding

- CNC gear hobbing

- 4-axis CNC milling

- High-production CNC turning

- Gear and sprocket shaping

- Laser cutting

- Induction heat treatment

- Broaching and keyseating

- Automated welding

- Complex Assembly

|

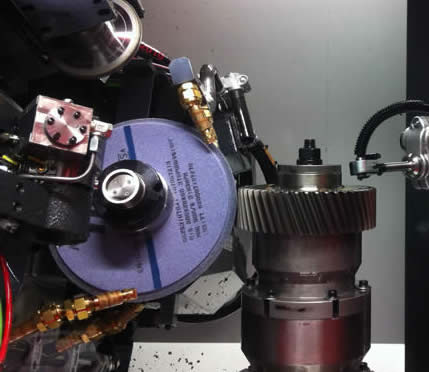

Profile gear grinding of a helical gear |

Gear Manufacturing Capabilities

Complete Gears

Gear Type |

Pitch |

Diameter

|

Facewidth |

Gear Accuracy |

External |

48 - 1.2 DP

(0.5 - 20 Mod) |

Up to 63 "

(1600 mm) |

Up to 30 "

(800 mm)

|

AGMA 2000 - Q14

DIN 3962 - Grade 3

|

Internal |

48 - 4 DP

(0.5 - 6 Mod) |

Up to 36 "

(900 mm) |

Up to 8 "

(200 mm) |

AGMA 2000 - Q10

DIN 3962 - Grade 7

|

Profile Gear Grinding up to 49" (1250 mm) diameter and 39" (1000 mm) facewidth. Click here for more information about our dedicated grinding hall and Höfler profile gear grinder.

Lean Manufacturing

GLI is committed to using lean manufacturing techniques and continuous quality improvement teams to achieve our vision of being a world-class manufacturer. We have active continuous improvement teams focused on Safety, 5S, TPM, Setup Reduction and Quality Systems. We use the following lean manufacturing techniques every day:

|

- 5S and Visual Factory

- Cellular Manufacturing

- Standardized Work

- Total Productive Maintenance

- Just-In-Time Production

- Pull Systems

- Mistake-proofing

- Quick Changeover

- Formal Problem-Solving

|

|